Strona główna  Forum

Forum

The term "3D printing" most commonly refers to the process of additive manufacturing that takes place on desktop equipment that is low in cost and has a limited number of functions. This is the most well-known form of additive manufacturing for the general public. Now, let's talk about additive manufacturing, shall we?Manufacturing that involves adding materials digitally is referred to as additive manufacturing, and it was introduced by Zuo Quanshan, who is the northern regional manager of Xi'an BLT Additive Technology Co. , Ltd. The traditional method of machining is referred to as the subtractive manufacturing method, while the methods of forging and casting are referred to as the equal material manufacturing methods.

Some people still believe that 3D printing has a fatal flaw because of the pores that are present in the structure of the printed object, despite the fact that the applications of additive manufacturing technology are extremely promising. Guo Chao, deputy director of the Institute of Additive Manufacturing Technology at the Tianjin High-end Equipment Research Institute at Tsinghua University, provided an explanation of this concept from both a technical and an application standpoint. According to Guo Chao, this phenomenon is real, but not all materials will exhibit this phenomenon. We were able to determine that the density of electron beam 3D printing has reached 99. 96% through the use of X-ray tomography, which is already a very high percentage and is very close to reaching full density.

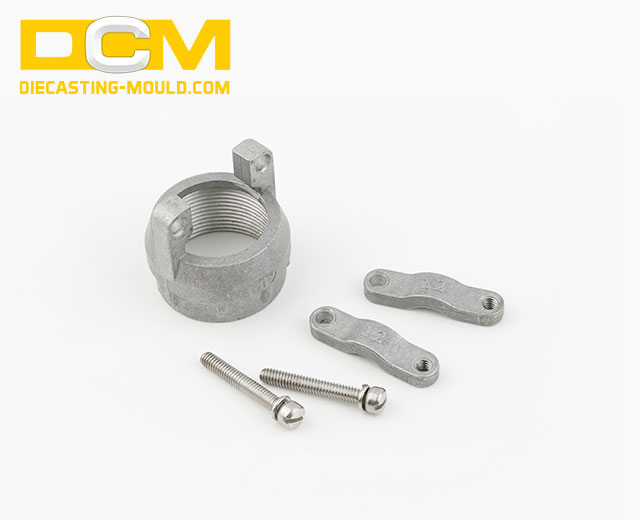

Some of the mechanical properties that correspond to the use of metal 3D printing technology in industry have also aroused the thinking of academics and industry insiders as the industry gradually begins to implement this technology. During the phase of technical conception, it is common to have questions such as, "Can the technology of metal additive manufacturing achieve extremely high mechanical properties?"Even so, there are experts aluminum die castings in prototyping who claim that the performance of the parts obtained by the current rapid prototyping technology is not very high, and that the parts can only be used for prototyping. During the period of time when technological development is taking place, people will inquire once more about how to achieve the performance of forgings in materials that are cast.

In point of fact, the answers to these questions have gradually become clear as a result aluminum alloy die casting of the extensive advancement of the application and transformation of technology associated with metal 3D printing. According to Zuo Quanshan, the mechanical properties of products made through metal additive manufacturing are primarily manifested in three aspects: uniform composition, basically no macro segregation from powder forming to small molten pool solidification; dense material, smooth solid/liquid interface, and full shrinkage can be achieved; Small tissue, can achieve rapid solidification. This demonstrates that the additive forming principle does not preclude the possibility of achieving extremely high mechanical properties, as can be seen from what has been presented here. As long as the material properties of the forming point are high, and as long as the points and points, roads and roads, and layers are well combined, the manufacturing technology for metal additive materials is fully capable of achieving extremely high mechanical properties.

During the course of his research, Guo Chao was confronted with a number of challenges, one of the most significant being the mechanical challenge posed by 3D printing. Those who are familiar with 3D printing, and more specifically 3D printing with metal, are aware that one of the most important considerations for 3D printing is to minimize stress and avoid deformation while the object is being printed. According to what Guo Chao said, the level of stress increases in proportion to the magnitude of the temperature difference. On the other hand, the current technology for metal electron beams has a higher energy density and powder bed temperature, which enables the integration of manufacturing and heat treatment. During the printing process, it is difficult to deform or crack, and it does not require the follow-up of metal materials, as is necessary with more conventional methods of manufacturing. procedure involving heat treatment.

Zuo Quanshan explained that the application of the technology of metal additive manufacturing in the field of aerospace zinc alloy die casting factory is reflected in four aspects: high-performance repair, manufacturing of extremely complex structural parts, functional enhancement, and weight reduction. Using AeroMet of the United States as an example, the company uses laser stereoforming technology in metal additive manufacturing to shorten the maintenance cycle of the wing spar in the F15 fighter jet to one week. Additionally, the replacement cycle of the corroded and damaged parts of the F15 aircraft is greatly shortened due to the use of this technology. Laser stereoforming technology is used to repair single-crystal turbine blades at the Swiss Federal Institute of Technology in Lausanne. The laser repair time for damaged blades in the repair of single-crystal turbine blades is only one to three minutes per piece.

Over the course of the last few years, rapid development in the field of medical implants has followed the path from standardization to individualization. According to Guo Chao, the current trend in domestic and international markets is the use of standardized implants. The next trend, however, is personalization, which means that each bone implant is not only different in size, but also different in shape and appearance. Because it is so tightly integrated with CT scanning technology, 3D electron beam printing allows the bone to be customized according to the individual circumstances of the patient. The scanned results can quickly form the required restoration through the use of digital methods, and the physical components can be directly produced after the drawings have been sent. The doctor will be able to perform surgery on the patient and receive the implant within seventy-two hours.

A special secondary grid-like structure is printed onto the surface of 3D printed skeletal components. This structure is a bionic one that mimics the bones of the human body and is a feature that is readily apparent about these components. Following the implantation of this structure within the human body, the bone may grow directly into the component that was printed using electron beam technology, creating a very good biological fixation. Because of this, electron beam 3D printing is currently enjoying a great deal of success in the medical sector. Guo Chao is of the opinion that the application of 3D printing in orthopedics will quickly cover the entirety of the medical industry in just five to six years from now.

Guo Chao has high hopes that the technology behind metal 3D printing will one day give more consideration to the independence of its core components, such as electron guns, supporting power supplies, focusing scanning coils, and height coil drives. The process of 3D printing is both an organized endeavor and an exhaustive collection of potential solutions. In order to create a database titled "Material-parameter-property," it is necessary to place primary emphasis on the independence of the primary material process. This includes everything from powder materials to process parameter packages to roughness, density, chemical composition, strength, fatigue, and other properties. In addition, Guo Chao has expressed the hope that 3D printing + will place a greater emphasis on civilian use, which is also going to be an important trend in the progression of 3D printing in the years to come.